Week 4

The design thinking week

Week 4: The design thinking week

In this week the trainer for us is Mr Luciano Betoldi, who hails from Protugal. He is guru to Mr Francisco Sanchez. To be frank this I was not at all regular in attendance. I had to stay away most of the time from the lab.

Day 1: Brainstroming

Necessity is the mother of Innovations

Luciano started the day by explaining on what designing thinking is all about. It involves cycle of activities Ask Imagine Plan Create Improve. Here desiging is made based on a problem identified and is purely based for a particular situation and ma not be applicable to the masses. Luciano made a demonstration of the Brainstroming activity for us. The session began with listing out what are the things that are not available in the fablab. So we all shouted items one by one. He started listing it down in the white board. He then took the problems one by one made us think how to solve the problem . Well that was really an interesting experience.

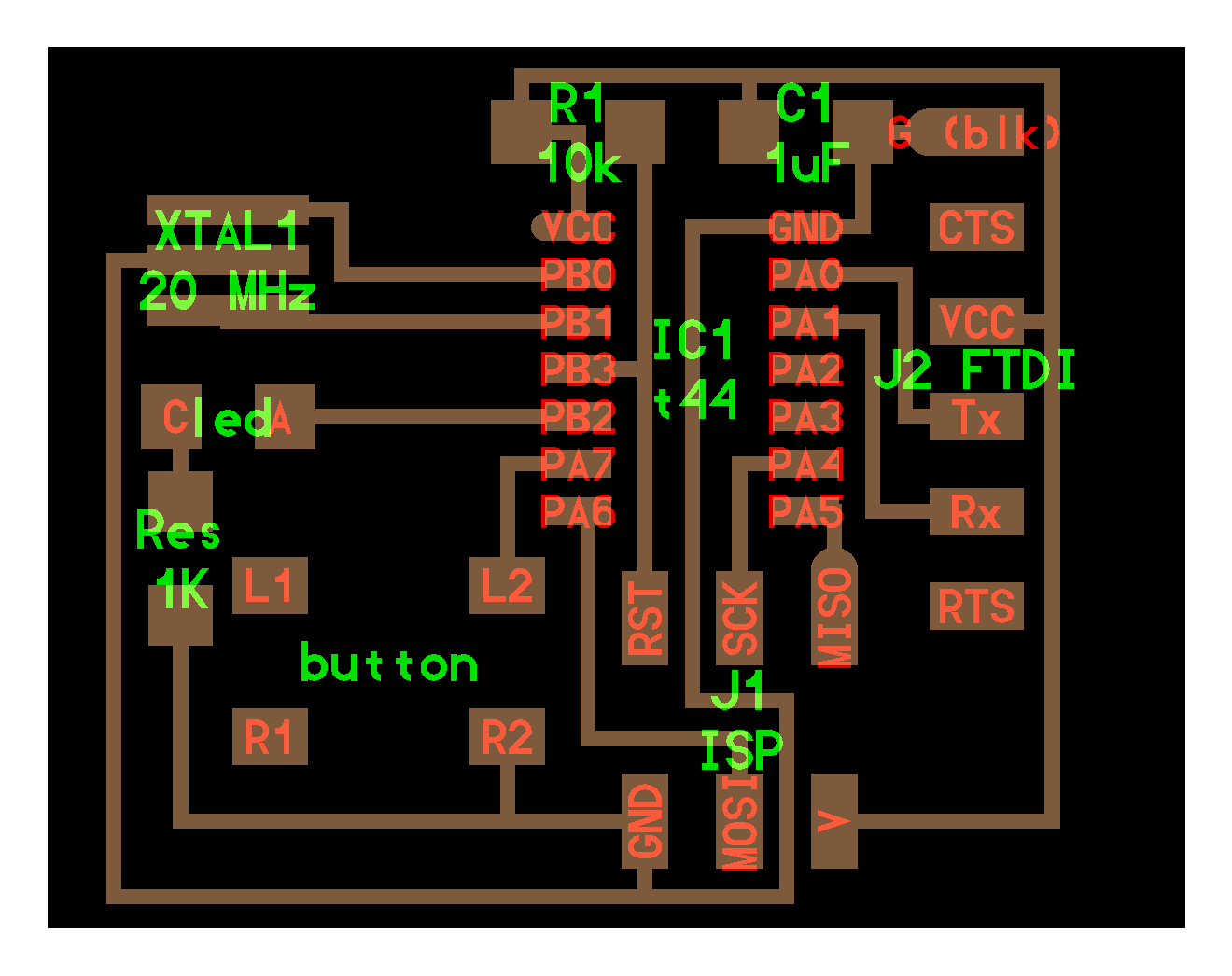

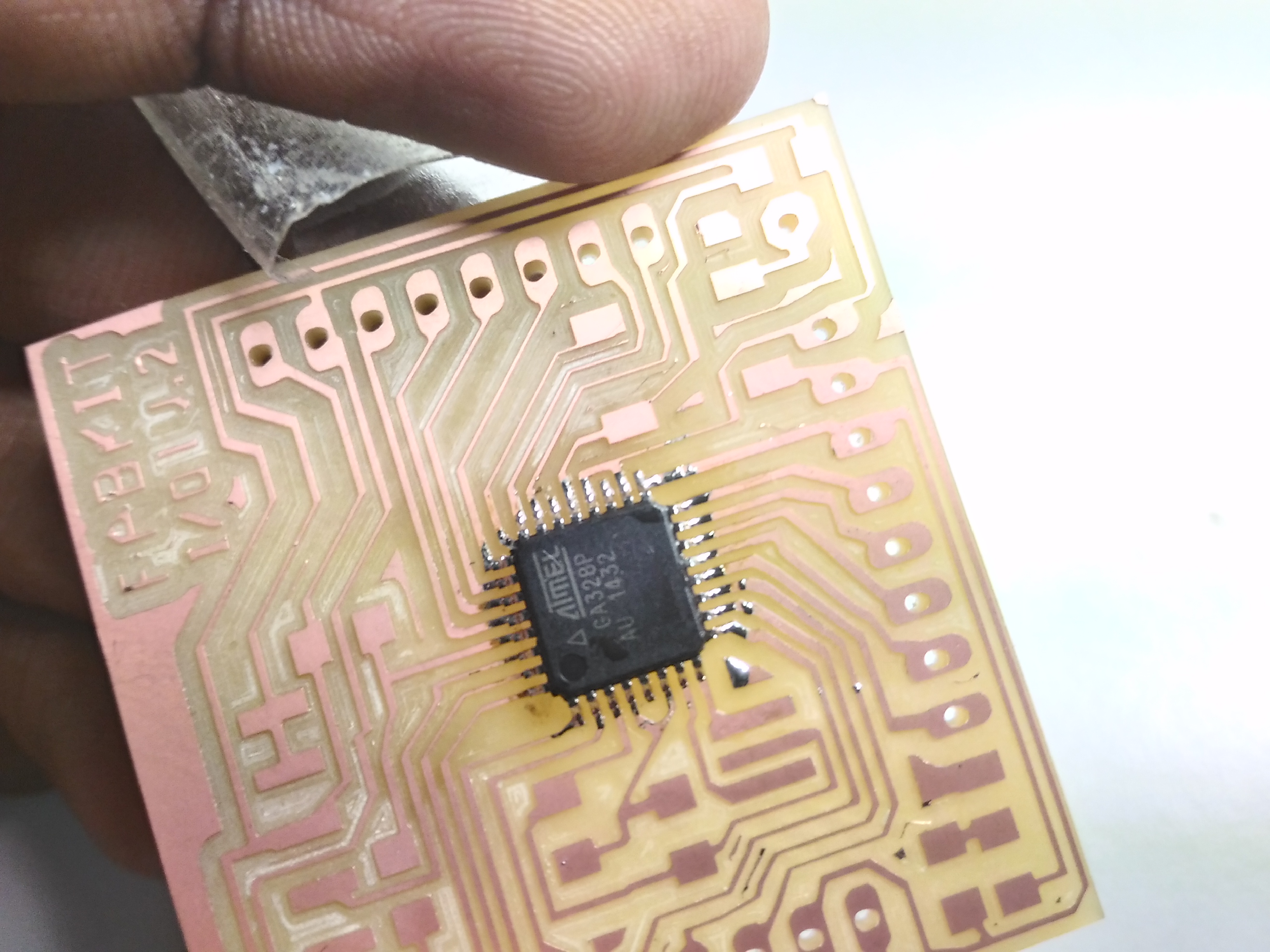

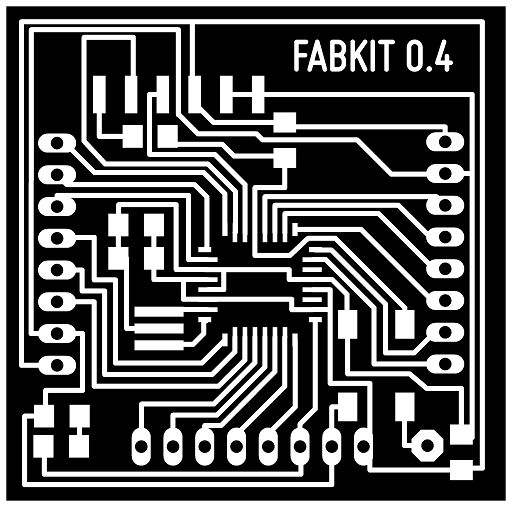

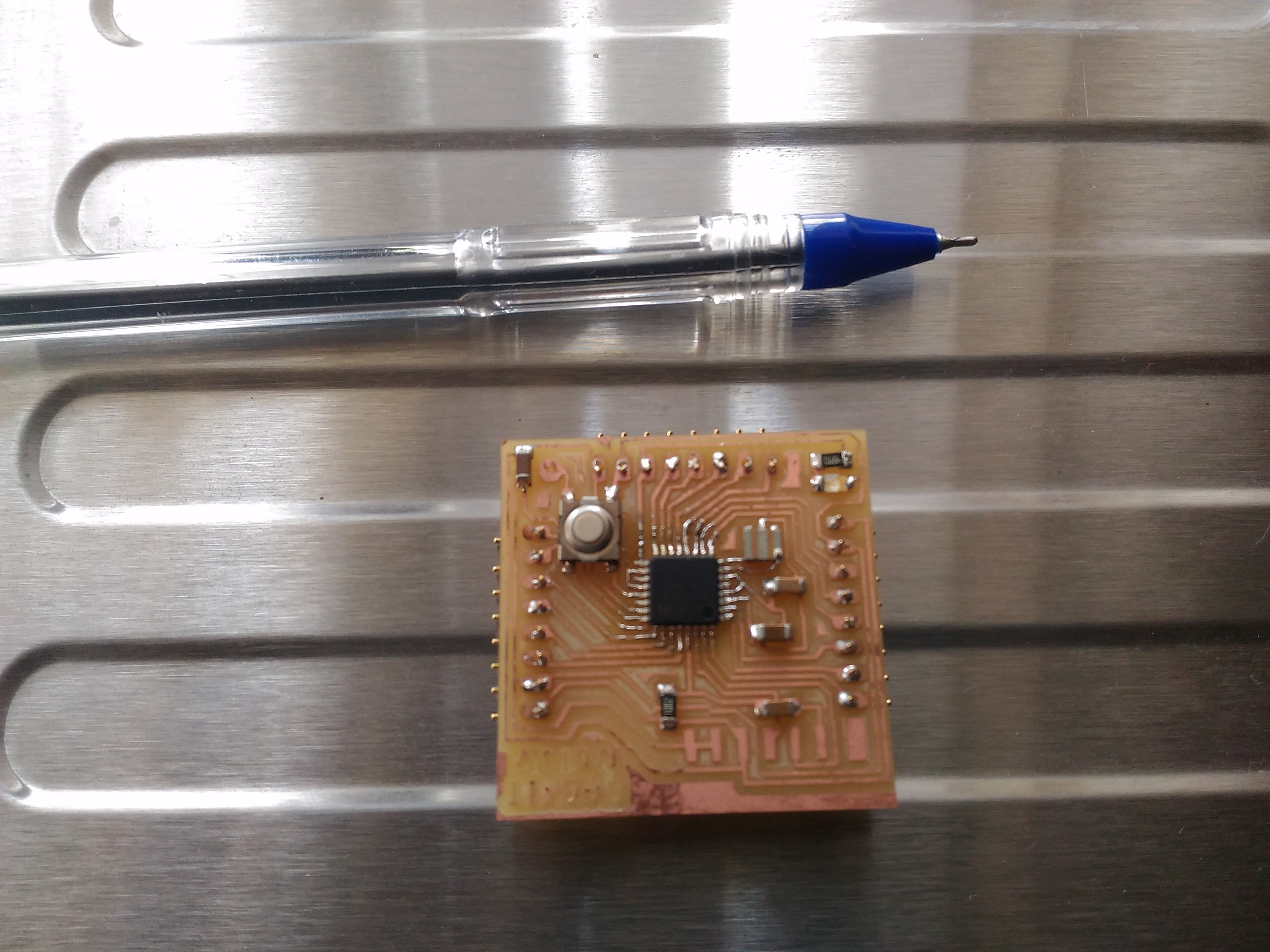

Later that day, Luciano explained on the Fabduino board. He gave us the details and asked to try it out. He milled out fabduino pcb. The core of the Fabduino is the Atmega328. To solder the legs of this processor one by one is a very difficult task so Luciano taught us an easy way to solder it. Fix any one leg in the corner accurately in the PCB. After that he simply poured in the solder to legs of the processor. He then placed copper braid over the legs placed the solder ion on top and gently removed it. It was one of the perfect soldering I have ever seen. Likewise he removed all the excess solder from the board. Its not really easy as it seems. I found it really difficult when I tried out the same shown below.

Day 2: Heads on with the Rhino

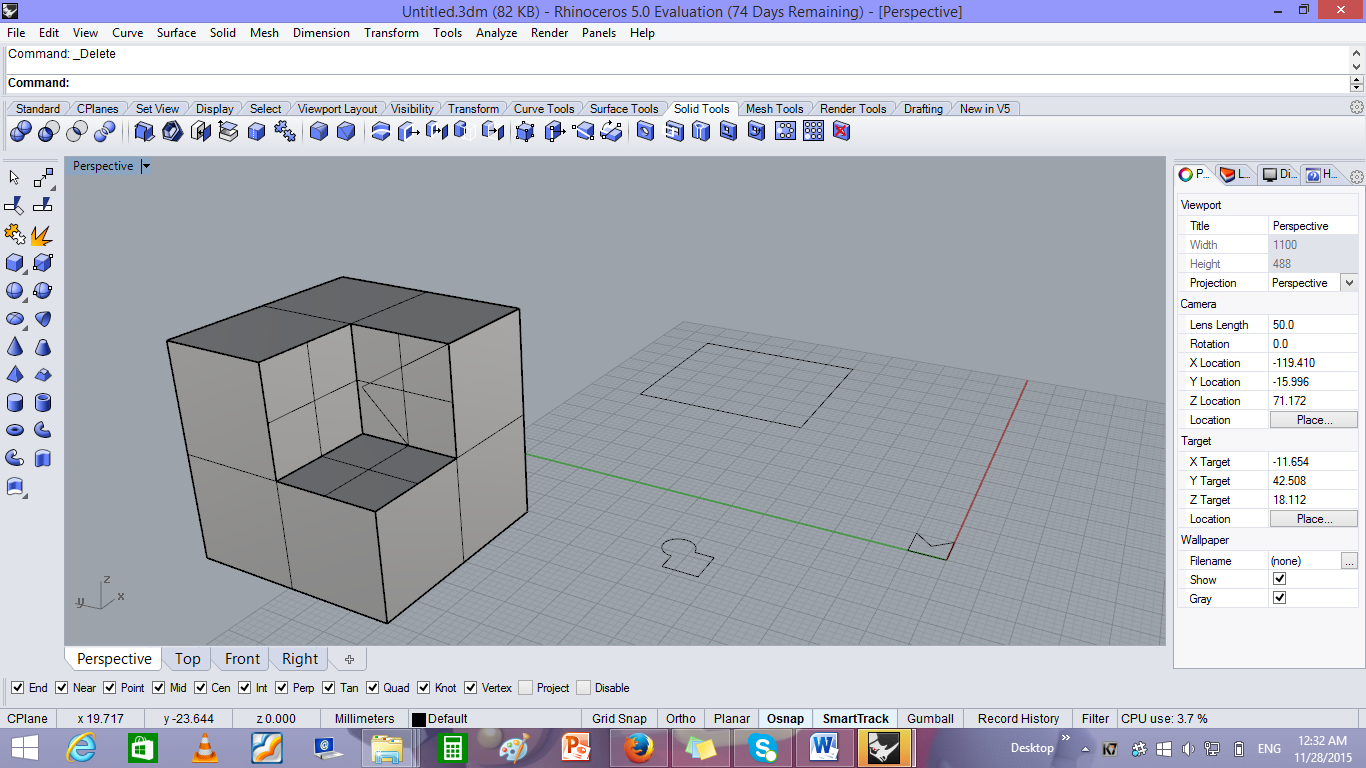

Today I came to fablab a bit earlier, tried out the fabduino board and completed stuffing it which I left behind the other day. As soon as I finished I was called in to the office and I rejoined in the late evening It was when Luciano was introducing Rhino, the design software. He gave some tips and asked us to make some shapes using the software. It was really interesting to play with it.

It was when Luciano was introducing Rhino, the design software. He gave some tips and asked us to make some shapes using the software. It was really interesting to play with it.

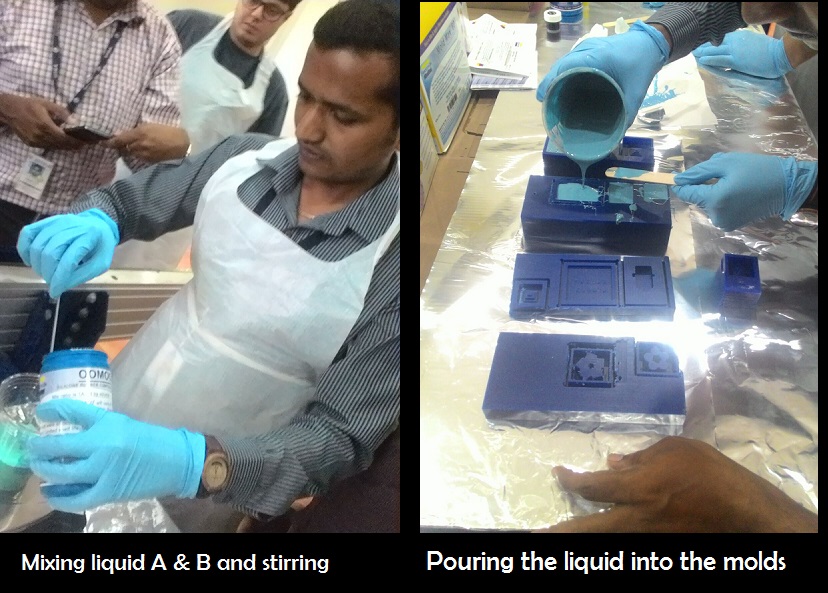

Day 3: The final mold

From the time of setting up the fablabs in Trivandrum and Cochin, I had some inclination towards the Molding and Casting. Most of them had prepared the mold using the wax and Roland Modela. And when Luciano asked who is interested for Molding nothing stopped me from stepping in. I was asked to wear an apron and gloves. There are few types of silicone rubber and plastic rubber in our lab’s inventory, Luciano pointed out the need to read the manual given along with the molding liquid. There are two types of kiquid in a single pack. It has to be mixed as per the total volume of the mold. For accurate mix the liquids are taken using a small weighing unit so that we can have the sufficient liquid. After pouring the two liquids together I stirred them for about 2minutes. The plastic rubber taken here is Oomoo 25 which starts to solidify in 30 mins After mixing I poured it over the molds until it fills in the mold completely. To remove the iar bubbles completely from the mold tap the mold towards the ground continuously, this makes the air to escape from within. It will get solidified in another 20 mins.